The Science of Filtration: How AirPop Blocks 99% of Particles

Electrostatic capture, mechanical interception, and multi-layer media engineering — discover the science that allows AirPop masks to filter out 99% of airborne particles while remaining remarkably breathable.

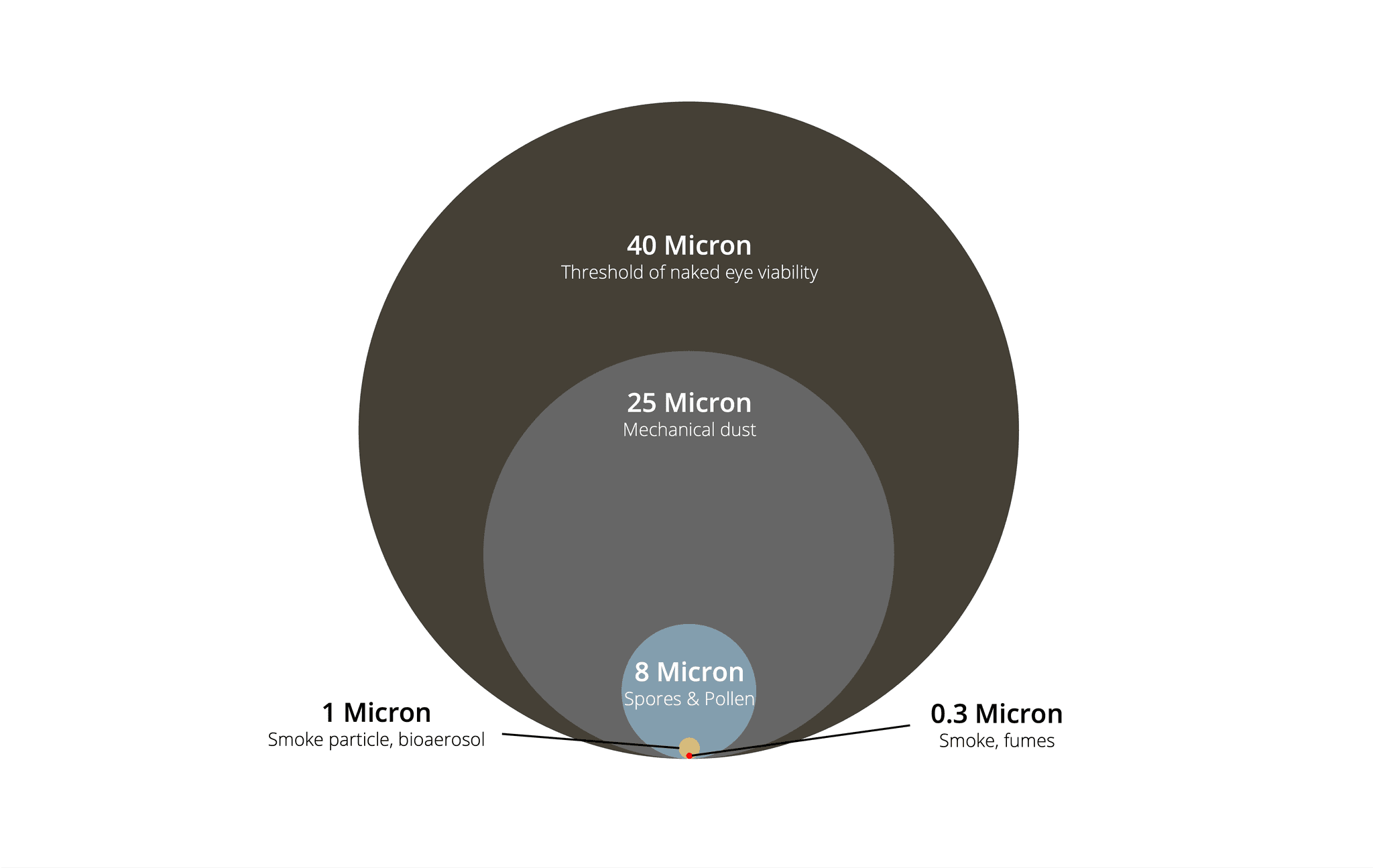

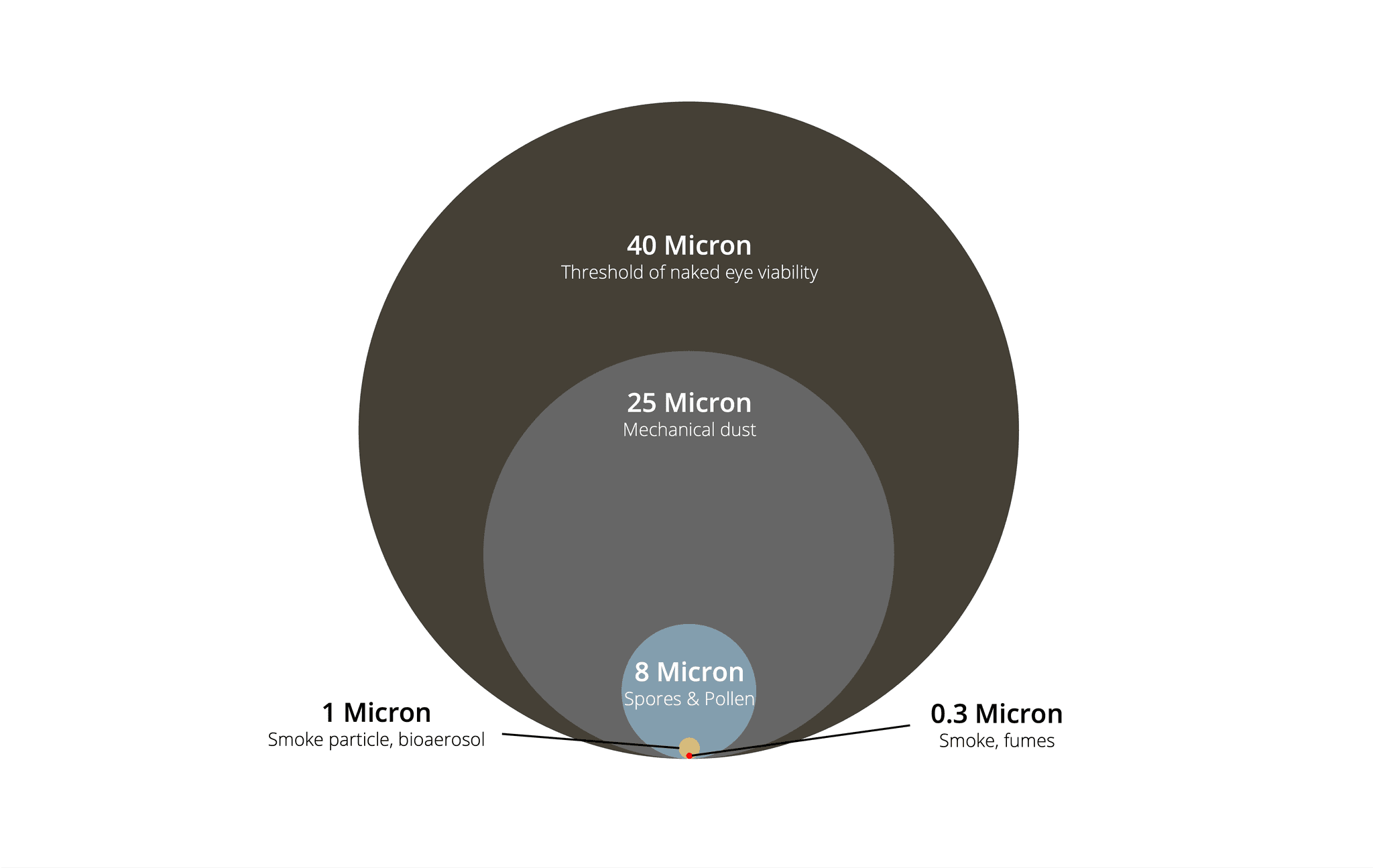

Filtering 99% of airborne particles sounds straightforward. In reality, it is an engineering challenge that requires mastering multiple physical mechanisms, optimizing material properties at the molecular level, and solving the structural problem of sealing filter media against the variable geometry of a human face. This article explains the science behind how AirPop achieves >99% particle filtration efficiency — and why the 0.3 micrometer particle size is the critical benchmark.

The Three Mechanisms of Filtration

Airborne particles do not all behave the same way as they encounter filter media. Depending on their size, mass, and velocity, different physical mechanisms capture different particles. High-performance filters exploit all three simultaneously.

Inertial Impaction

Large, heavy particles (generally above 1 micrometer) have enough inertia that they cannot follow the air stream as it bends around filter fibers. Instead, they collide directly with the fibers and stick. Think of it like a car that cannot make a sharp turn at high speed — the particle's momentum carries it into the fiber. This mechanism is most effective for larger particles and at higher air velocities.

Diffusion

Very small particles (generally below 0.1 micrometer) are so light that they exhibit Brownian motion — random, zigzagging movement caused by collisions with gas molecules. This erratic path increases the probability that these tiny particles will contact a filter fiber and be captured. Diffusion is most effective for the smallest particles and at lower air velocities, where particles have more time to wander into fibers.

Electrostatic Attraction

Many high-performance filter media, including the meltblown polypropylene used in AirPop filters, are electrostatically charged during manufacturing. This permanent electrostatic charge creates an electric field that attracts particles — much like a statically charged balloon attracts hair. Electrostatic attraction is especially effective for mid-range particles that are too small for efficient inertial impaction but too large for strong diffusion effects.

At approximately 0.3 micrometers, particles are too large for efficient diffusion capture and too small for efficient inertial impaction. This makes 0.3μm the "most penetrating particle size" (MPPS) — the hardest size to filter. This is precisely why filtration standards like N95 and KN95 test at this particle size. If a filter works at 0.3μm, it works even better at all other sizes.

Multi-Layer Filter Architecture

AirPop filters use a multi-layer construction where each layer serves a specific function. The outer layer provides structural support and captures large particles and droplets. The middle layer — the primary filtration media — is electrostatically charged meltblown polypropylene that captures fine and ultrafine particles through all three mechanisms described above. The inner layer provides comfort against the skin and captures moisture from exhaled breath before it can degrade the electrostatic charge of the middle layer.

The 3D Aerodome: Structural Engineering for Filtration

Filter media performance is only half the equation. The other half is ensuring that air actually passes through the filter rather than leaking around it. This is where AirPop's 3D Aerodome structure becomes critical. Inspired by architectural dome principles, the Aerodome creates a rigid three-dimensional form that holds the filter material away from the wearer's face. This design serves multiple purposes simultaneously.

- Increased surface area: the dome shape exposes more filter media to airflow, reducing resistance per unit area

- Off-face breathing: the air chamber between face and filter eliminates the hot, damp microclimate of flat masks

- Structural integrity: the 3D form prevents collapse during inhalation, maintaining consistent airflow across the filter

- Seal optimization: the dome perimeter creates a consistent contact surface for the 360° face seal

Why Breathability and Filtration Are Not Trade-Offs

The conventional wisdom in respiratory protection has long been that higher filtration means lower breathability — you can have one or the other, but not both. AirPop's engineering challenges this assumption. By increasing the effective filtration surface area through the Aerodome's dome geometry, air velocity through any given point of the filter is reduced. Lower velocity means lower breathing resistance. Meanwhile, the total filtration efficiency is maintained because the aggregate surface area more than compensates. The result: >99% filtration with 2x the breathability of a standard N95.

Every performance claim AirPop makes is backed by third-party testing at accredited laboratories. Filtration efficiency, breathing resistance, and seal integrity are all independently verified to meet or exceed ASTM F3502, NIOSH, FDA, KN95, CE, and BSI Kitemark standards.

“The physics of filtration are well understood. The engineering challenge is applying those physics in a form factor that people will actually wear for eight hours a day.”

— AirPop engineering team

Related Articles

Understanding Mask Certifications: ASTM, NIOSH, KN95 and Beyond

ASTM F3502, NIOSH N95, KN95, FFP2 — mask certifications can be confusing. This comprehensive breakdown explains what each standard tests for, how they differ, and which certifications actually matter for everyday protection.

Understanding PM2.5: The Invisible Threat to Your Health

PM2.5 particles are too small to see, but their impact on your lungs, heart, and brain is anything but invisible. Learn what PM2.5 is, where it comes from, and how to protect yourself every day.